-

Hydraulic WorkoverAbstract:

Hydraulic Workover is the most cost efficient method to repair all types of wells both onshore and offshore.

Details

Hydraulic Workover is the most cost efficient method to repair all types of wells both onshore and offshore. The Hydraulic Workover Unit (HWU) is a versatile, cost saving and safe tool to perform sand cleanouts, change-out completions and to repair casing leaks. By fixing wells quickly and very cost efficient, Balance Point Control has become the market leader for Hydraulic Workover services in the North Sea.

• Completions / Workover

• Plug & Abandonments

• ESP completion

• Sand screens installations

• Tubing conveyed perforations

• Liners and tailpipe installation

• Repair of down hole safety valves

• Well deepening

• Fishing/ Well clean-outs

• Casing window milling

• Casing repairs

• Packer / Plug Milling

• Cementing

• And much more….

A HWO unit can cover the same working envelope as a workover rig but has advantages over conventional rigs or hoists for certain applications, such as:

· Very cost efficient

· Small and flexible footprint

· Small environmental impact

· Design for offshore use

· Quick (de)mobilisation

· Versatile

· Perfect control

· Modular approach

Hydraulic cylinders can generate large pull and push forces and give the HWO unit a small footprint and layout. These properties are especially beneficial for offshore operations where space is limited and where weather conditions can be harsh. In general is the running speed of a HWO unit lower than that of conventional workover rig.

Application:

• Completions / Workover

• Plug & Abandonments

• ESP completion

• Sand screens installations

• Tubing conveyed perforations

• Liners and tailpipe installation

• Repair of down hole safety valves

• Well deepening

• Fishing/ Well clean-outs

• Casing window milling

• Casing repairs

• Packer / Plug Milling

• Cementing

• And much more….

Advantages of Hydraulic Workover:

A HWO unit can cover the same working envelope as a workover rig but has advantages over conventional rigs or hoists for certain applications, such as:· Very cost efficient

· Small and flexible footprint

· Small environmental impact

· Design for offshore use

· Quick (de)mobilisation

· Versatile

· Perfect control

· Modular approach

How does it work?

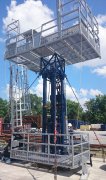

Hydraulic Workover is a well intervention technique which can be used to install or remove tubular (pipes) in- or out of dead wells. “Dead” well means that the well has zero surface pressure and has a heavy fluid or mud in the wellbore, or is not capable of sustaining natural flow. The pipes are pulled out of the well using hydraulic cylinders.Hydraulic Power

The HWO unit (Hydraulic Workover Unit) utilizes hydraulic cylinders to lift the tubular in- or out of the well. The use of hydraulic cylinders allows perfect control over tubular movements and eliminates the use of a large mast construction which is present on conventional drilling rigs.Hydraulic cylinders can generate large pull and push forces and give the HWO unit a small footprint and layout. These properties are especially beneficial for offshore operations where space is limited and where weather conditions can be harsh. In general is the running speed of a HWO unit lower than that of conventional workover rig.